A C-Suite Blueprint for Intelligent Operations and Digital Transformation

Most companies today believe they have already completed their digital transformation. They have moved apps to the cloud. Use digital tools instead of paper. Track data on screens instead of paper files. This is good progress, but in 2025, this is only the starting point. It is just the basic level of digitization every business is expected to meet.

The real question for leaders is simple. Now that your business is digital, is it intelligent? Can your systems see what is happening across the company?, Can they learn from patterns?, Can they act on their own without waiting for people to manually push every button?

This is where Intelligent Operations come in. It is the next big leap for organizations that want to grow faster, operate smoother, and stay ahead of competitors. This blog gives you a clear and practical blueprint that any C-suite leader can follow to bring intelligent operations into their company.

While 89% of companies have already adopted a digital-first business strategy, only 20% have achieved the level of maturity needed to realize significant value from it.”

McKinsey’s “Digital Transformation” or Gartner’s Hype Cycle reports

The Digital Ceiling: Why Transformation is No Longer Enough

Over the last decade, digital transformation focused on moving from manual processes to digital tools. For example, instead of writing inventory logs on paper, companies now track them on software. Instead of calling someone for updates, teams now use dashboards or cloud apps.

These improvements create efficiency, but they do not create intelligence.

A spreadsheet does not warn you about a future shortage. A dashboard does not tell you why sales will drop next week. A digital tool can show information, but it does not understand it.

This is what we call the digital ceiling. Companies reach a point where they have digital tools, but they are still reactive. They still wait for problems to happen before acting.

To break past this ceiling, businesses need systems that sense, predict, act automatically, and learn continuously. That is what Intelligent Operations delivers.

Reactive maintenance can cost up to 3-5 times more than proactive, predictive maintenance, according to a Forrester analysis of industrial IoT.

Forrester TEI study on predictive maintenance

To understand how leading companies are moving beyond this digital ceiling, watch our video: “Unlocking Business Success with AI: How Impressico Drives Innovation and Optimization”.

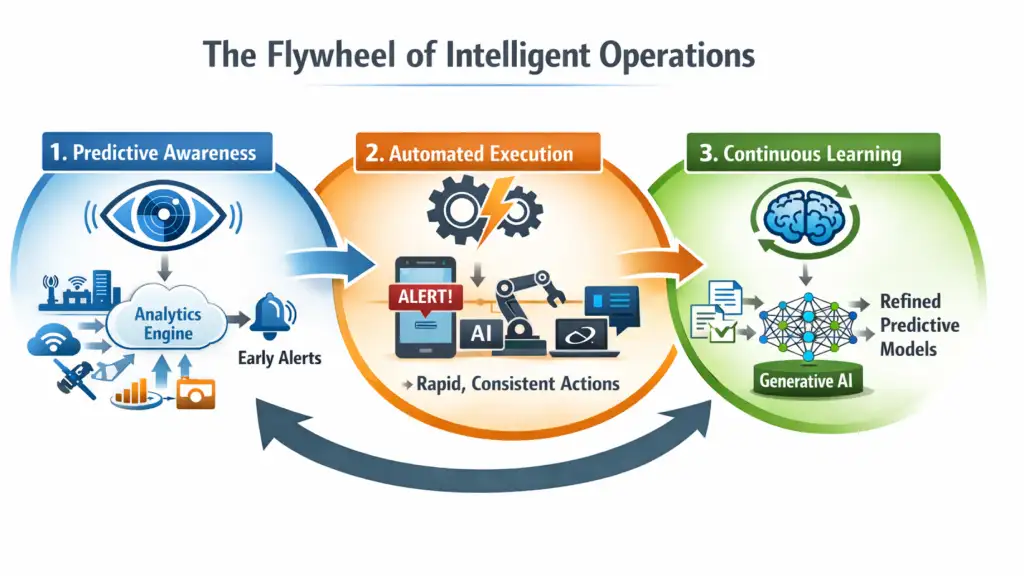

The Three Pillars of Intelligent Operations

As a C-suite leader, you can think of Intelligent Operations as a system made of three powerful pillars. These pillars work together and must be part of the fabric of the organization.

The three pillars are:

- Predictive Awareness

- Automated Execution

- Continuous Learning

Let’s look at each one in simple terms.

Pillar 1: Predictive Awareness – From Reactive to Proactive

Predictive Awareness gives your business a “sixth sense.” Instead of waiting for something to break, your systems can spot signals early and alert you before things go wrong.

This pillar is powered by:

- IoT sensors that monitor equipment, inventory, or supply chain conditions

- Real time data collection

- AI and analytics platforms that study patterns and send early warnings

The goal is simple. Move from reacting to problems to preventing them.

Gartner predicts that by 2026, organizations that operationalize AI transparency will see a 50% improvement in adoption, business goals, and user acceptance.”

From Gartner’s AI trends

Why it matters for leadership

When your operations can predict issues before they occur, you reduce downtime, save costs, and keep customers happier. Predictive awareness also helps leaders make smart decisions because you can see what is coming, not just what already happened.

At Impressico, we integrate data from existing IoT sensors to monitor everything from machine health to inventory freshness. This real-time data flows into our AI analytics engine, giving you early warnings and actionable insights powered by predictive models—so you can prevent breakdowns and shortages instead of reacting to them.

Pillar 2: Automated Execution – Embedding Intelligence into Workflows

Once your systems can predict what is coming, the next step is letting them act on that information automatically. This is what Automated Execution does.

Automated Execution combines:

- AI

- Workflow automation

- DevOps tools

- Mobile apps for on the ground actions

The idea is that when an alert or prediction appears, the system can initiate recommended actions within clearly defined guardrails – ensuring no absurd or risky decisions are executed without human review or approval. This balances speed and automation with safety, control, and accountability

According to an MIT Sloan Management Review study, companies that integrate AI with workflow automation report cycle time reductions of up to 70% in core processes.”

Why it matters for leadership

Leaders often deal with bottlenecks caused by slow handoffs. Someone sees an issue, someone else approves action on it, and another team fixes it. The delay costs money.

Automated Execution cuts this delay. It creates a smooth path from data to action. This means faster cycles, fewer mistakes, and more consistent results.

Impressico builds intelligent workflows that respond automatically to predictive alerts. For example, if a system predicts a temperature rise in a storage unit, the workflow triggers an automatic fix. DevOps automation deploys the update. Mobile apps send instructions to the nearest field team. The result is a closed loop where execution happens quickly and smoothly.

Pillar 3: Continuous Learning – The Self Improving Organization

The third pillar takes operations to a whole new level. Continuous Learning means every outcome in your business feeds back into your system so the system becomes smarter over time.

This is powered by:

- Generative AI

- Machine learning models

- Outcome analysis

- Feedback loop analytics

Continuous learning helps your systems improve themselves, just like a person who learns from experience.

McKinsey research highlights that ‘AI high performers’- those deriving significant value, are twice as likely to have mature MLOps and feedback loop systems in place, enabling this continuous learning.

Why it matters for leadership

C-suite leaders want sustainable growth. Continuous learning creates a business model that improves each month. This reduces errors, improves forecasting, and increases speed.

Impressico uses Generative AI to study outcomes from real operations. Our tools identify what went well, what failed, and what can improve. The system then fine tunes recommendations for the next cycle. Over time, your entire operation becomes more adaptive and smarter.

The Blueprint in Action: A Cross Functional Case Study

To understand how the three pillars work together, let us look at a real world example. Imagine a large company that runs food services for corporate offices.

Step 1: Predictive Awareness

IoT sensors track inventory levels and ingredient freshness in real time. The AI system detects that a particular ingredient is approaching its expiry date because current consumption is slower than forecasted. Recognizing a potential surplus if no action is taken, the system sends an early alert so teams can adjust usage, promotions, or procurement and avoid waste.

Step 2: Automated Execution

The system then creates a new menu idea using that ingredient. Impressico’s digital recipe tool sends the idea to the chef. The menu board updates automatically. The procurement tool adjusts future orders to avoid overstock.

No manual coordination. No delays. No waste.

Step 3: Continuous Learning

After the new dish is served, customers provide feedback through a simple app. AI analyzes the reviews. It discovers which taste profiles are preferred. It then adjusts future menu recommendations.

From start to finish, the operation learns and adapts. This is Intelligent Operations in action.

🔍 From Framework to Real-World Impact

Explore a detailed application of the Intelligent Operations blueprint in our industry-specific white paper.

“AI-led Travel Booking: Personalize & Automate Experiences”

Discover how leading travel companies use AI for predictive personalization, automated workflows, and continuous experience optimization.

The C-Suite Playbook for Implementation

Here is a simple and direct plan that leaders can use to start implementing the blueprint.

1. Diagnose

Pick one core operational area that is costly or critical for your business. It might be:

- Inventory

- Customer service

- Field operations

- Manufacturing

- Logistics

Start with the process that matters most.

2. Infuse

Now apply the three pillars:

- Add predictive awareness using sensors, data streams, and analytics

- Build automated workflows so that insights trigger actions

- Add continuous learning so the system improves after each cycle

You do not need to rebuild everything at once. Start with one process and expand.

3. Measure and Scale

Calculate the return on investment.

Look at cost reduction. Look at speed improvements. Look at revenue gains.

Once you see the value, scale the same model across other areas of the company.

This playbook gives leaders a clear and safe path to move from digital operations to intelligent ones.

Conclusion: Intelligence is the New Operation

Today, operational excellence depends on operational intelligence. Digital tools alone are not enough anymore. Companies that build Predictive Awareness, Automated Execution, and Continuous Learning will not only run better but also set new standards in their industries.

The next frontier belongs to businesses that think and act intelligently.

Move beyond transformation. Let Impressico help you implement the Intelligent Operations Blueprint. Schedule Your Strategy Session with Impressico today.

Leadership FAQs: The C-Suite Blueprint for Intelligent Operations & Digital Change

-

What’s the main difference between Digital Transformation and Intelligent Operations?

Digital Transformation focuses on replacing manual processes with digital tools (e.g., spreadsheets for paper). Intelligent Operations is the next stage, where those digital systems use AI, IoT, and automation to predict, act, and learn autonomously.

-

How long does it typically take to implement an Intelligent Operations framework?

Implementation is iterative, not a one-time event. Using the diagnose-infuse-measure blueprint, organizations can see value in a single core process within 3-6 months, then scale gradually.

-

Is Intelligent Operations only for large enterprises with big IT budgets?

No. The modular, pillar-based approach allows companies of any size to start small in one critical area (e.g., inventory management) using cloud-based AI and IoT services, proving ROI before wider investment.

-

What are the biggest risks, and how do you mitigate them when automating execution?

The key risk is uncontrolled automation. Mitigation is achieved by embedding “clearly defined guardrails” and human-in-the-loop approvals for critical decisions, ensuring safety and accountability are built into the workflow.

-

How do you measure the ROI of Intelligent Operations?

Key metrics include reduction in operational downtime, decrease in waste/costs (like predictive maintenance savings), improvement in process cycle times, and revenue growth from enhanced customer experiences and agility.